Products

-

1/8″ 1/4″ 3/8″ Stainless steel high pressure spray nozzle tip,Flat Fan Pattern Nozzle, tee jet spray nozzles flat fan

Application:

Coating,Cleaning,presentment,washing,decreasing,photostatting,defenestration,lubricating,cooling ,humidifying,dust suppression,fire

fighting, etc and electronics, molter vehicles, food, steel, chemistry, environmental protection. -

High Pressure 1/2″1/4″1/8″ Anti clog Stainless steel vee jet flat spray nozzles

Applicable industry: Hotels, Garment Shops, Building Material Shops, Manufacturing Plant, Machinery Repair Shops, Food & Beverage Factory, Farms, Restaurant, Home Use, Retail, Food Shop, Printing Shops, Construction works , Energy & Mining, Food & Beverage Shops, Advertising Company

-

3/4 Metal Dust Control Spiral Nozzle 316ss Spray Nozzle

Nozzles Have Closed Relationship To Our Work And Life

Qianqin Has a wide range of products, ranging from general cleaning nozzles to high pressure mist and high pressure cleaning nozzles, from work piece cleaning to environmental chemical destining, depressurization to etching and cleaning of electronic circuit boards, from photostatting to humidification, lubrication, steel phosphorylation and so on.

We can see almost every industrial having the nozzles usage, it is small part but playing a important role. -

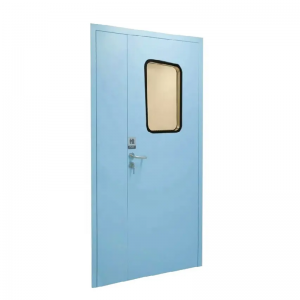

Pharmaceutical Swing Single Blue Color Door With 50mm Door Frame

The clean door is suitable for occasions requiring shortcuts such as purification workshops, food factories, pharmaceutical

factories, laboratories, hospitals, and operating rooms.The surface of the galvanized sheet is sprayed with baking paint, which

meets the requirements of hospital purification level.The door mold is formed in one day, seamless and corrosion-resistant.It is

professionally used in hospitals, pharmaceutical factories, microelectronics factories, food processing workshops and

laboratories, and other places that need to be clean, hygienic and airtight. -

Stainless Steel #304 Air Shower Pass Box wth Voltage120V/60HZ or 220v/50HZ

Clean room air shower pass box for laboratory/hospital/pharmaceutical factory

Pass box is one of the cleanroom systems, which is used to transfer materials from one side to other side through controlled environment in order to avoid airborne cross contamination. As the name states itself, the primary and only work of a pass box is to pass material from one side to other without raising contamination concern and if any particulate matter presents on the material surface, it swipes away during the operation. Interlocking door mechanism is the prime feature of a pass box, when door at one side is open the door at other side remains closed. It is popular with other names such as cleanroom pass through, clean transfer window and transfer hatch; in addition, it is widely used in microbiology laboratories in food, pharmaceutical and chemical industries.

-

High quality mirror surface SUS304 vertical air flow FFU

FFU is applicable for Class 10-100000 dust-free workshops, which is convenience the overall use of group control system.

FFU is also applicable for manufacturer-class optical, biological industries of semiconductors,electronics, flat panel displays and disk drives, and other areas with strictly control requirements for air pollution.

-

FFU laminar flow portable clean booth for air dust

Clean booth is also called non-dust working room.It’s the fastest and most convenient simply equipped clean room.It has multi-kinds of classification and space collocations, can be designed according to customer’s request.

The main structure consists of stainless steel square pipe or aluminum alloy square pipe;Air flow is provided by Fan filter unit(FFU);Surrounded by anti-static curtain or tampered glass;With the flange cover in the top to reach a sealed zone,the inside cleanness will reach Class100~100000;

-

Qianqin 4*2 HEPA Fan Filter Unit For Clean Room AC FFU Support OEM/ODM

Specification MODEL NO. QH-570H QH-570B QH-570J QH-1170T L*W*H(MM)(Picture 1) L*W*H(MM)(picture 2) L*W*H(MM)(picture 3) L*W*H(MM)(picture 4)) External Size 575*575*250 1175*575*250 1175*575*230 1175*575*277 HEPA SIZE 570*570*69 1170*570*69 1170*570*69 1170*570*69 Cleanliness Class 100 @ 0.3um(FED CRETERION) Air Volumn 550-750m³/h 800-1350m³/h 800-1350m³/h 1000-1800m³/h Air Velocity 0.55–1.2m/s±20%(Adjustable) Efficiency 99.99% @ 0.3um–99.99999%@0.12um(Optional)Neu... -

Restaurant Warehouse Traffic Swinging Door Double Action Swinging Door

Specification MODEL NO. QH-570H QH-570B QH-570J QH-1170T L*W*H(MM)(Picture 1) L*W*H(MM)(picture 2) L*W*H(MM)(picture 3) L*W*H(MM)(picture 4)) External Size 575*575*250 1175*575*250 1175*575*230 1175*575*277 HEPA SIZE 570*570*69 1170*570*69 1170*570*69 1170*570*69 Cleanliness Class 100 @ 0.3um(FED CRETERION) Air Volumn 550-750m³/h 800-1350m³/h 800-1350m³/h 1000-1800m³/h Air Velocity 0.55–1.2m/s±20%(Adjustable) Efficiency 99.99% @ 0.3um–99.99999%@0.12um(Optional)Neu... -

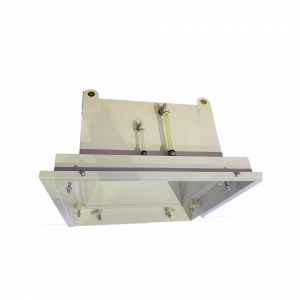

Clean room HEPA terminal filter Air Supply Unit box with GEL Filter

The high-efficiency air outlet structure includes static pressure box, diffuser plate, air inlet flange, high-efficiency air filter, pressing device and bolts.

According to the structure, the high-efficiency air outlet can be divided into top delivery and side delivery.

There are two types of matching filters: ordinary filters with partitions and filters without partitions.

Among them, filters without partitions are divided into two types: dry filters and liquid tank filters. The high-efficiency air outlet with dry filters is mainly used. In the electronics industry, the high-efficiency air outlet of the dosing tank filter is mainly used in the pharmaceutical industry.

The air outlet surface diffuser is divided into three types: round hole type, louver type and cyclone type.

The air inlet is divided into two types: with air valve and without air valve -

Galvanized Steel Laminar Air Flow Hood Fan Filter Unit Module

Introduction Fan filter unit (FFU) is air cleaning equipment to supply purified air to the clean room for manufacturing semiconductor, liquid crystal, etc. The installation space is the system ceiling grid. For a large clean room, the number of required FFU is from several hundreds to several thousands. Concept of FFU development 1. To reduce running cost by saving energy; 2. To reduce construction cost and term by thin, light and compact structure; 3. To reduce initial cost by total design o... -

High Speed PVC Plastic Fast Rolling Shutter Door for Warehouse

Features 1. adopt Germany imported motor Grand brand, good quality 2. 3 years warranty for the motor 3. dimension is customized as customer’s requirement 4. adjustable rolling speed 3-10s 5. used between clean room and dust room, can allow fork go through 6. can install on air shower 7. door material: industrial cloth+PVC 8. door frame: SS304 stainless steel material Products Description Product Name PVC High Speed Shutter Door Door Curtain Thickness :0.8mm~1.5mm Material: PVC Co...

+86-18038493642

+86-18038493642